by Tae-in Chun

Dongdaemun, the Beginning of Korean Baseball Brands

The roots of Korea’s baseball equipment industry began in the alleyways surrounding Dongdaemun Stadium in Seoul. In the early 1970s, sporting goods shops that had been scattered throughout Jongno and Euljiro gradually gathered around the stadium, naturally forming a commercial district. Here, every task needed for baseball was carried out, from glove repair and production to bat processing and uniform embroidery and number patching. In an era when overseas brands were difficult to access, what mattered most to players was not the brand name, but which shop’s craftsman had made the equipment. Dongdaemun was not only a famous shopping district, but also the heart of Korean baseball equipment manufacturing.

Although Dongdaemun Stadium was demolished in a redevelopment project in 2009, its culture did not disappear. Merchants spread out to large commercial complexes such as the 16-story Good Morning City, Jamsil Sports Mall, and areas around Euljiro. Even today, through this network, many amateur baseball teams, youth clubs, and women’s baseball teams continue to produce uniforms and team equipment. Only the location has changed. Dongdaemun still functions as the practical center of Korea’s baseball equipment industry.

The Origins of Handmade Gloves: Gimhae Industrial Company and JOE LEE

The point at which glove manufacturing in Korea took shape as an industry dates back to 1967 in Eomgung-dong, Busan. Gimhae Industrial Company, founded by the late Gwang-jo Lee, was Korea’s first specialized baseball glove factory. Every process was done by hand. From leather cutting to stitching, steam molding, and final lacing, skilled workers participated in each stage through a division of labor.

Despite passing through multiple crises, including the IMF financial crisis, competition from low-priced Chinese products, and the recent pandemic, Gimhae Industrial Company’s production system has been maintained. In 1991, the premium brand JOE LEE was launched, inheriting the philosophy of Gwang-jo Lee. It continued a production approach focused on craftsmanship rather than mass production, and its performance was proven in actual play by professional players including Hyun-jin Ryu. JOE LEE remains a symbol of domestically made gloves crafted by artisans. It is a case that shows the Korean baseball equipment industry has accumulated real manufacturing expertise beyond simple distribution.

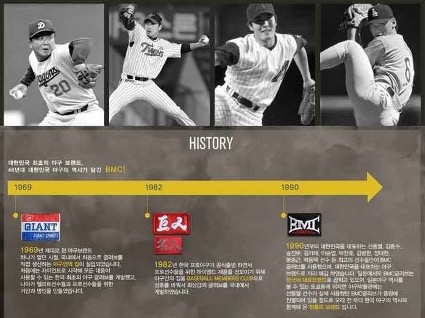

The Growth of Korea’s First Brand, BMC

The representative Korean domestic brand is undoubtedly BMC. It began in 1969 by producing player gloves under the name “Giant,” and was reorganized under its current brand name following the launch of the KBO in 1982. It then rapidly gained popularity by combining professional player sponsorships with distribution network expansion. In bromide photos from the 1990s and 2000s, most players wore BMC gloves, and it was also the most commonly encountered brand in the Dongdaemun commercial district.

From the late 2000s, BMC expanded its direction toward a premium strategy. To pursue high-end positioning, new products of the highest quality were required. Through this process, the Alkan and Royalty series were created. These series use Seto and Terada line leathers processed by Maruhashi in Japan, materials also used in top-tier Mizuno models. When Japanese brands productize gloves with the same materials, they are priced very high, but BMC maintained domestic production systems and kept prices relatively reasonable. As a result, it earned a reputation in the field as a “high-quality glove with strong value for money.”

Trust Built Alongside the League

BMC has long been active as an officially certified KBO brand. It has consistently supplied official game balls, umpire equipment, and team goods, growing alongside the league on the field. In the 2025 season as well, it continues to handle production of official game balls and the supply of umpire equipment. By releasing collaborative products with teams and the league, such as team-character snapback caps, it is also expanding its points of contact with fans.

By steadily building brand self-reliance, BMC has established a position that is not easily replaceable on both the distribution and manufacturing sides. Within this flow, brand operations are currently centered on Fusion Sports Korea (FSK). Multiple baseball brands such as Kang’s Studio, Diamond, and Morimoto are managed together, forming a relatively stable supply structure that spans equipment production to distribution. A brand that began in the alleyways of Dongdaemun has grown to a position where it supplies standard equipment used in the league.

At present, the Korean baseball equipment market includes a range of brands centered around BMC, including SPS, Incojava, Fandom Korea, and Atoms and Altis, each building its own domain. SPS has expanded overseas distribution through entry into the Japanese market. Incojava operates high-end lines using Japanese Seto leather and American Texas steerhide, and also handles OEM production for Louisville Slugger and Easton. Fandom Korea has earned a dedicated following with its North Skip leather models, while Atoms and Altis are targeting the premium market based on Japanese manufacturing technology.

Behind this growth are advancements in production processes such as the adoption of Maruhashi leather, hydraulic vacuum processing, uniform stitching, and steam molding. Korean brands no longer remain as inexpensive alternatives. From producing official league equipment to engaging in global OEM collaborations, the manufacturing culture that began in the alleyways of Dongdaemun continues quietly today.